PRODUKTY

Čistiaca chémia / čistiace rolky

Čistiaca chémia

Microcare

MicroCare je špičkou v oblasti rýchleho, účinného, bezpečného a nákladovo efektívneho čistenia dosiek plošných spojov počas výrobného procesu a procesu opráv na montážnej linke SMT. MicroCare by malo byť vašou prvou voľbou pri čistení elektroniky.

Čistiace rolky

R2R Diversified Sdn Bhd

Spoločnosť R2R bola založená v roku 2000 v Malajzii. Od roku 2000 spoločnosť R2R vyrába a špecíálne utierky, vrátane perforovaných utierok pre používateľov sieťotlačových tlačiarní SMT / SMA / SMD v odvetviach EMS na celom svete.

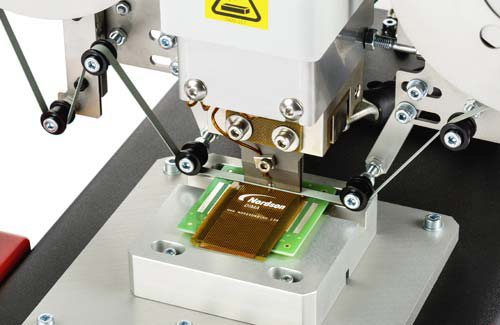

NORDSON DIMA

https://www.nordson.com/en/divisions/dima/products/bonding-and-soldering-sys tems

Nordson DIMA poskytuje systémy pre Hot Bar Soldering od stolových aplikácií cez samostatne stojace systémy až po plne aizované in‐line systémy spájkovania, spájania teplom, ACF laminácie a Heat Seal Bonding aplikácií.

Nordson DIMA poskytuje systémy pre Hot Bar Soldering od stolových aplikácií cez samostatne stojace systémy až po plne aizované in‐line systémy spájkovania, spájania teplom, ACF laminácie a Heat Seal Bonding aplikácií.

C‐Drive Head

C‐Drive Head

The C‐Drive Bond Head is designed to deliver quality solder joints and Heat Seal bonds consistently. When coupled with a C‐Flow Controller, Temperature, Force, and Displacement Monitoring give…

C‐Flow Controller with touchscreen

C‐Flow Controller with touchscreen

The C‐Flow Controller stands alone from other pulsed heat controllers with its unique integration of responsive temperature control and useful tools such as displacement monitoring and force control,…

C‐Base with touchscreen

C‐Base with touchscreen

The C‐Base Bonding/Soldering system is a combination of a CFlow and a C‐Drive module and stands alone from other pulsed heat controllers with its unique integration of responsive temperature control…

C‐Prime with touchscreen

C‐Prime with touchscreen

C‐Prime Desktop System for Heat Seal Bonding, ACF Laminating, Hot Bar Reflow Soldering and Heat Staking, handles the product in a fixed position, with an optional fixture, size up to 300 x 200 mm.

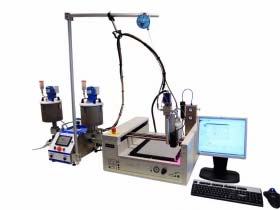

C‐TurnFlux

C‐TurnFlux

The C‐TurnFlux is the topline product for aed Flux Dispensing in combination with aed Hot Bar Reflow Soldering. An ultimate system for high end applications, where output and quality…

C‐Tack with touchscreen

C‐Tack with touchscreen

C‐Tack Desktop System for ACF Laminating, also called Pre‐Tacking or Pre‐Bonding.

Gen3 Systems

Gen3 Systems Limited is a specialist British manufacturer of test and measurement equipment used to predict reliability and maintain quality in the production of electronic circuits.

Gen3 Systems Limited is a specialist British manufacturer of test and measurement equipment used to predict reliability and maintain quality in the production of electronic circuits.

They specialise in:

- Solderability

- SIR and CAF reliability measurement techniques

- Electronic circuit cleaning and cleanliness testing (ROSE Testing)

- Conformal coating

- Solder paste analysis

Solderability

The MUST System 3 is the latest technological evolution of the original Multicore Universal Solderability Tester (MUST) that grandfathered all modern solderability test standards. It remains the unquestioned industry benchmark for solderability testing.

Capable of measuring down to 0.001mN the MUST is THE most accurate and comprehensively equipped test system of its type in the world.

The MUST3's dimensions and weight are as follows;- 81L x 34W x 52H cm

Cleanliness

CM Series

Although commonly referred to "Cleanliness Testing" it is in fact a measurement of ionic contamination. This test method has, for over 40 years, been acknowledged as an important Quality Assurance and Process Control tool in the manufacture of electronic circuit boards, components and assemblies.

The CM+ Series utilise a solid gold measuring cell, ballistic amplifier and a vigorous pumping system to achieve superior measurement accuracy of <0.005mS/cm even at very low conductivity values. The CM+ Systems have been designed to avoid polarisation effects between electrodes as might occur when using DC test currents.

CONTAMINOMETERS from Gen3 Systems come in 5 different models and 5 different tank sizes because when selecting a Test System, it is important to use the smallest possible tank size for the circuit under test.

SIR and CAF

AutoSIR 2

Surface Insulation Resistance Testing System. Measuring changes in surface insulation resistance.

The Gen3 Systems AutoSIR 2 system represents a dramatic improvement over existing SIR test alternatives, and its shielded precision electronics allows state-of-the-art accuracy resistance measurements to be made up to 1014 Ω.

The key features of this system are:

- Measurement Time: 256 Channels

- Applied Voltage: +1V to 1000V

- Measurement Range: 106 Ω to 1014 Ω

- Measurement Method: Continuous on all selected channels

- Measurement Test Intervals: Fully Selectable from minimum of 1 minute

AutoCAF 2

Conductive Anodic Filament Monitoring System. Measuring the influences of sub-surface electro-chemical reactions.

AutoCAF is able to measure up to 256 individual measurement sites under conditions of high humidity and temperature in accordance with IPC-TM-650 2.6.25 Test Method & IPC 9691 CAF Test Users Guide.

The key features of this system are:

- Measurement Time: 256 Channels

- Applied Voltage: +1V to 1000V

- Measurement Range: 106 Ω to 1014 Ω

- Measurement Method: Continuous on all selected channels

- Measurement Test Intervals: Fully Selectable from minimum of 1 minute

Solder Paste Analysis

SPA1000

The SPA 1000 Solder Paste Analyser.

A unique six-in-one test system used to characterise solder paste in compliance with both IPC and IEC Standards.

The SPA 1000 also introduces new process control capability by accurately measuring the suitability of the solder paste prior to its implementation on the production line. It achieves this by determining the "Open-Time" for the paste. It also performs the Slump Test and both of these methods provide a "Go/No Go" answer in less than 30 minutes to ensure minimum delay for the production line.

ELITE AUTOMATIC CO., LTD

https://www.elitego.com.tw/ec/

Spoločnosť ELITE Automatic Co., LTD bola založená v roku 1989 a za svoju viacej ako 30 ročnú históriu si vybudovala dobré meno v SMT priemysle. ELITE má sídlo v Taipei, odkiaľ poskytuje klientom technickú pomoc a servis.

Spoločnosť ELITE Automatic Co., LTD bola založená v roku 1989 a za svoju viacej ako 30 ročnú históriu si vybudovala dobré meno v SMT priemysle. ELITE má sídlo v Taipei, odkiaľ poskytuje klientom technickú pomoc a servis.

Na trh dodáva zariadenia na rezanie (frézovanie) dosiek plošných spojov v prevedení off‐line a on‐line vrátane aického odoberania a triedenia.

EM‐5700N OFF LINE Cutting Machine

EM‐5700N OFF LINE Cutting Machine

Specification

- Sliding table positioning mode:Cylinder positioning double sliding table

- Maximum working range on one side(W*D):600*620 mm

- Working height:920mm±20mm

- Cutting speed:1~100 mm/s

- Mechanical repeatability:± 0.01 mm

- Control System:PC‐based 3 Axis controller

- Drive way:AC Servo motor

- working system:IPC Windows 10

- Cutting accuracy:± 0.1 mm

- Spindle speed:Max. 60000 rpm

- Host voltage:1φ, AC 220V 50/60Hz

- Air supply:4~6 kg/cm², flow:1500 L/hr

- Power consumption:1.4 KVA

- Dust collection method:External type,upper exhaust type 2HP,See Catalog EV‐720

- Dust collection method:External type,lower exhaust type 3HP,See Catalog 3(5)HP

- Static elimination:Static elimination gun (lower exhaust type)

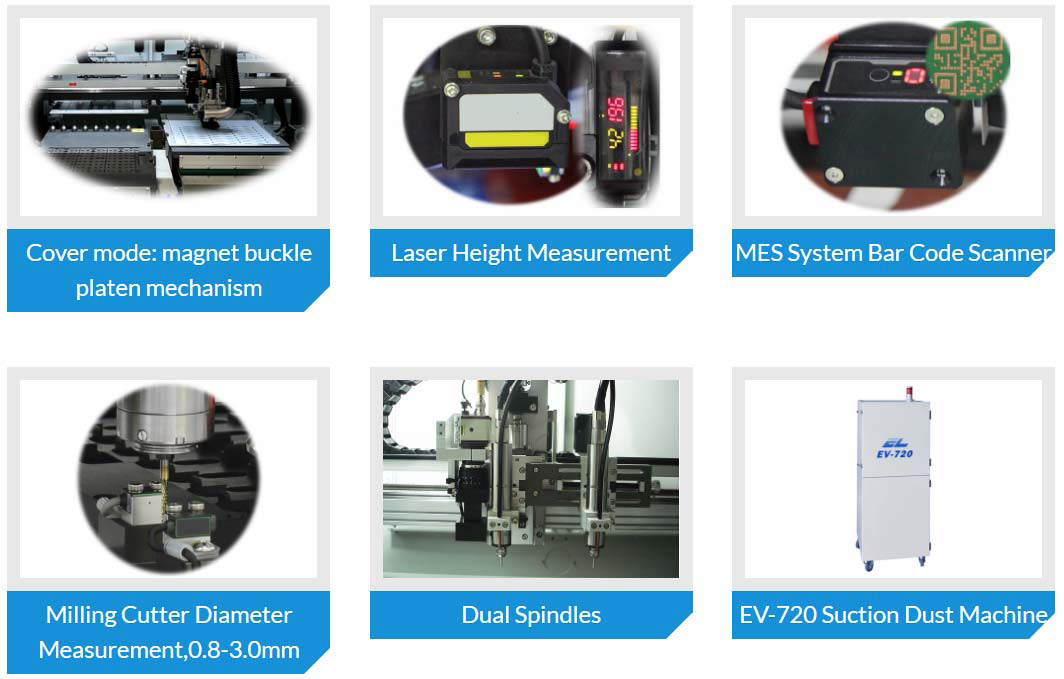

ER‐6000 AT IN LINE Cutting Machine

ER‐6000 AT IN LINE Cutting Machine

Specification

- Sliding table positioning mode: Servo precise positioning double sliding table

- Pick‐and‐place method: single‐head pick‐and‐place mechanism

- Cover mode: magnet buckle platen mechanism

- Maximum working range on one side(W*D):500*640 mm

- Working height:920mm±20mm

- Cutting speed:1~100 mm/s

- Mechanical repeatability:± 0.01 mm

- Control System:PC‐based 6 Axis controller

- Drive way:AC Servo motor

- working system:IPC Windows 10

- Cutting accuracy:± 0.05 mm

- Spindle speed:Max. 60000 rpm

- Host voltage:1φ, AC 220V 50/60Hz

- Air supply:4~6 kg/cm², flow:1500 L/hr

- Power consumption:3.0 KVA

- Dust collection method:External type,upper exhaust type 2HP,See Catalog EV‐720

- Dust collection method:External type,lower exhaust type 3HP,See Catalog 3(5)HP

- Front station conveyor belt height: 920 ± 20 mm

- Rear station conveying mode: belt type, rail type, carrier type,ES‐602 can be selected according to customer needs

- Flow direction: left to right, right to left

- Static elimination:Static elimination gun (lower exhaust type)

Optional:

NORDSON DIMA

https://www.nordson.com/en/divisions/dima

Dispenzery

DIMA JE TERAZ SÚČASŤOU NORDSON RODINY (Glogálny leader v dispenzovaní)

DIMA JE TERAZ SÚČASŤOU NORDSON RODINY (Glogálny leader v dispenzovaní)

Ponúkajú rôzne platformy a ventily v závislosti na aplikáciách dávkovania od dávkovania Underhill, tryskového dávkovania, zalievania, bariery, plnenia a tesnenia.